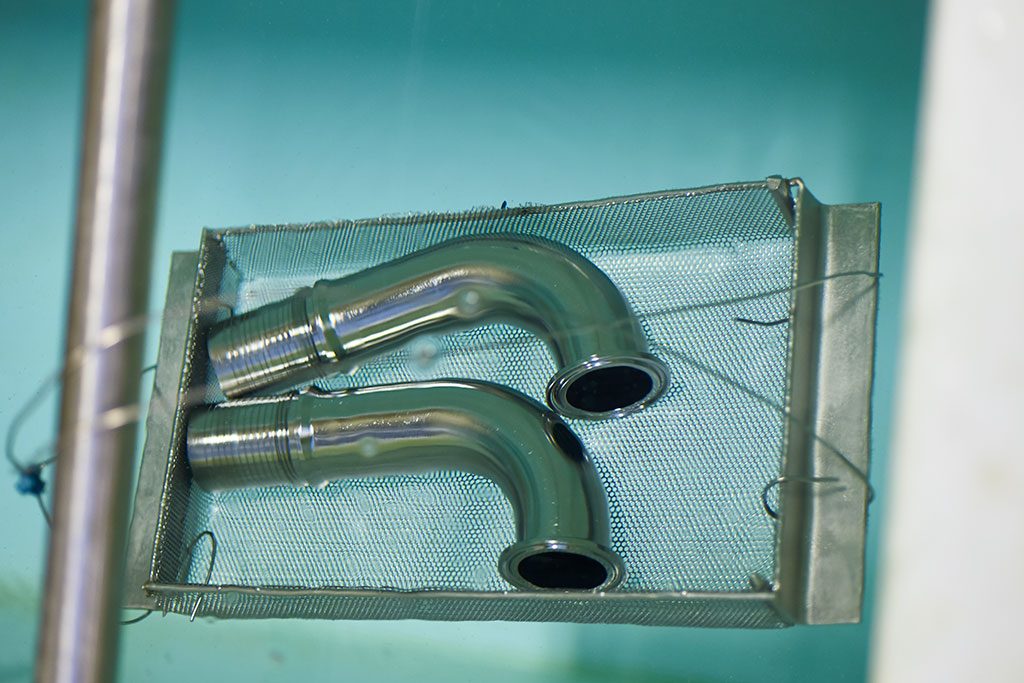

Passivation removes exogenous iron from the surface of stainless steels and higher alloys by means of a chemical dissolution, most typically by a treatment with an acid solution that will remove the surface contamination and enhance the formation or restoration of the passive layer. This passive oxide layer prevents further oxidation and cleans the parts of dirt, scale, or other welding-generated compounds.

Quality Fabricators is also able to passivate components that have been in service and are in need of repassivation. Call 603.905.9012 to discuss your project.

Quality Fabricators is also able to passivate components that have been in service and are in need of repassivation. Call 603.905.9012 to discuss your project.

We do not passify Electropolished components unless a customer specifies it because Electropolishing is considered an ultimate form of passivation as it not only removes iron, nickel etc. from the stainless, but leave behind a chromium rich passive layer as a result of the process.